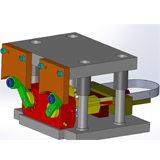

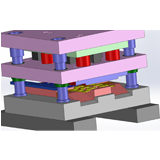

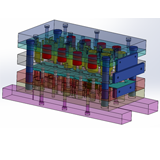

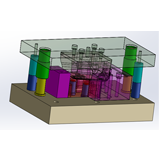

With its general outline our general process of mould manufacturing consists of designing, prototyping, machining, to montage and proofing.

We carry out design, moulding and part manufacture from a single centre. Mould production specifications are carried within our own firm synchronized with the customer.

Moulding process is carried out by fully provide the necessity of the customer, products and the specific parts of it.

As to part producing we meet the determined standard conditions of the product and we plan the process to deliver the product on time.

After the confirmation of the customer, the design that is completed and its graph data is made suitable for the production after CAM programme is used to determine the surface engineering.

n.